Epicurium are a wholesale food and drink distributor based in the north of England. Their mission is to banish boring snacks and they offer a carefully curated range of products to their customers.

Promoted by an industry-wide rise in packaging prices in 2020 and 2021, Epicurium were looking to streamline their packaging materials and associated costs. At the same time, a rise in demand meant that Epicurium were also looking for ways to improve their productivity.

The Brief

- Introduce packaging solutions to help Epicurium reduce their operational costs

- Solutions need to help increase productivity and manage demand

The Solution

Experts from the Macfarlane Packaging team suggested several solutions, including:

Swapping from plastic tape to gummed paper tape

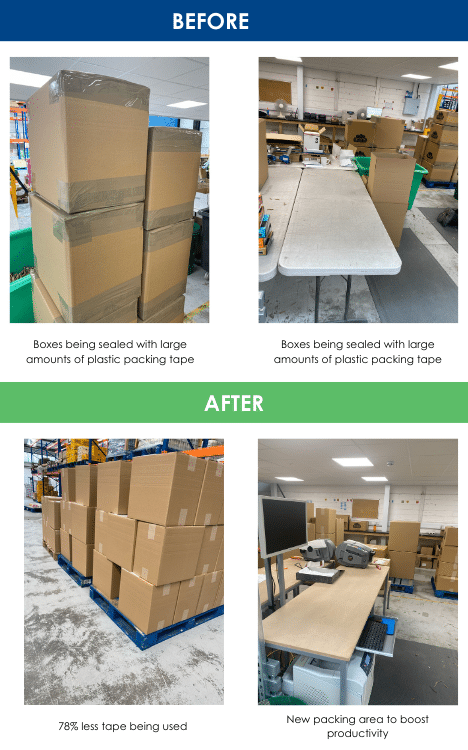

Epicurium were sealing boxes with standard plastic packing tape. This involved using up to 14 strips per box – an average of 7 metres.

Swapping to gummed paper tape has the potential to unlock cost-savings, as well as reduce material use. Only two strips, measuring 1.6 metres were required to seal each box.

Redesigning packing areas

To tackle efficiency challenges, Macfarlane re-designed Epicurium’s packing area. This meant that all packing materials and equipment were within easy reach and the design minimised down time that was being spend fetching packing materials from other areas in the warehouse.

The Results

78% reduction in packing tape material used

Less paper tape was needed vs. the previous solution

£2,000 saving per year

Offsetting rising costs in other areas by lowering tape costs

100% recyclability improvement

Tape can now be recycled with cardboard boxes

Improved productivity

The new packing area helped create a more efficient environment

What Epicurium have to say

“We work alongside 100s of retailers, all of which have their own sustainability goals. We’re increasingly seeing our snack brands move to plastic-free packaging too. Working with Macfarlane, and their initiatives, has meant we keep pace and help us in our aim of becoming a plastic-free business.”

Head of Technical & Operations