Three quick wins to reduce packaging use

When less packaging is used, you are not only reducing overall waste but business costs too. It’s a win-win situation.

Here are three quick wins that can reduce packaging use and uncover potential savings:

Use packaging that fits the product you are shipping

Sounds obvious right? But how many stories have we heard about customers receiving small items in huge boxes stuffed with paper. To combat this, have a range of box sizes on hand for packers. This will allow them to select the right box for the product footprint and minimise the amount of voidfill required.

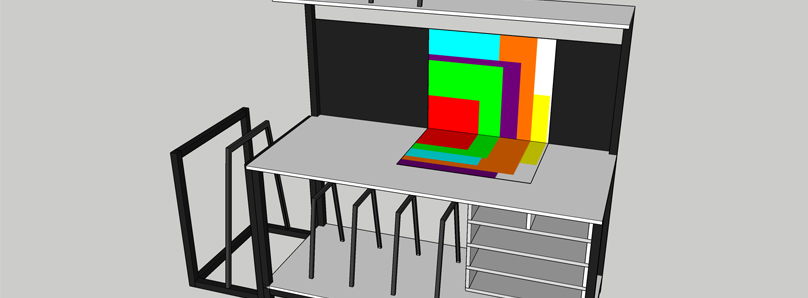

Retail and fulfilment operations often use shadow packing boards. These simple to use guides help packers to quickly identify the right size box to ship products in the most cost-effective way. They are custom made to match existing product lines.

Reducing overall pack size will also increase the number of parcels on a delivery vehicle. This reduces the supply chain carbon footprint and transport costs too.

Switch to better quality tape

Tape is a low-cost item on the packaging order form and if it costs pennies, does it really matter how much of it is used to seal a box?

Well, it is a material that uses energy to manufacture, and plastic tape is not recyclable. If you are using meters and meters of it to seal a carton (H taping, double applying over box seams etc), then it’s probably not the bargain you think it is. It also takes longer to apply lots of tape – slowing down packing time considerably and absorbing valuable labour.

A switch to a better-quality tape, or water activated gummed paper tape, means that you will use considerably less material. It may appear to be more expensive by the roll, but an analysis of the reduced amount needed, and time taken to apply per box, will reveal a cost saving. Paper tape is also 100% recyclable.

Reduce the amount of stretch wrap you use

If you are using high volumes of conventional machine stretch wrap, a switch to a performance film can dramatically reduce the amount of film required to achieve load containment. This will reduce the overall tonnage of plastic annually. So, ask one of our packaging professionals to conduct a stretch wrap audit. It won’t take long and could reduce your stretch wrap use by as much as 50%.

Why not contact Macfarlane Packaging today for more ideas on how to reduce the amount of packaging in your business and reduce costs.