A guide to packaging automation for small businesses

Research shows that 38% of online retailers are worried about meeting customers’ fast delivery expectations, so how do you deal with that as a smaller business?

Throughout the last 11 months, we’ve covered many topics in our Packaging 101 series, to develop your knowledge and small business packaging. This month, we want to explore something that can seem scary to a large portion of business…packaging automation!

We’ll break down stereotypes and discover why automation would be great for your operation, even as a smaller business.

Blog Content

- 1.

- 2.

- 3.

-

4.

Great automation solutions for small businesses

- 4.1.

- 4.2.

- 4.3.

- 5.

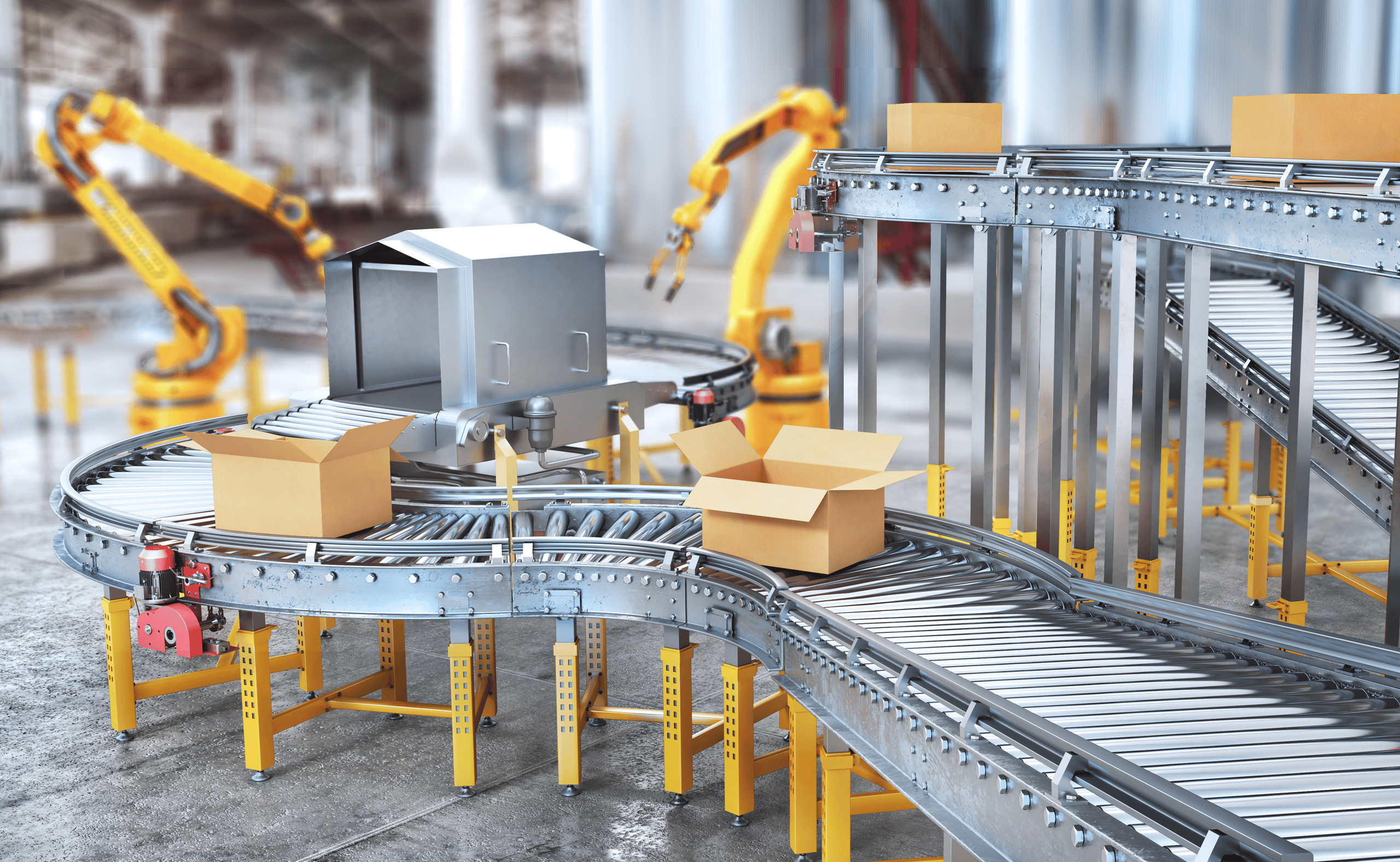

What is packaging automation?

Packaging automation is when you use packaging machinery (large or small) to help with your packing process. Often this can mean reducing human touch-points in your packing line. For example, this could include anything from automatically cutting tape when at the desired length; to automatically placing the products into a mailing bag ready for shipment.

Using automated packing systems essentially allows you to reassign valuable resource to high value tasks or in a way that better suits your operation. You can enhance most aspects of a packaging process, from picking and packing, through to conveying and wrapping. There are packaging machines for it all.

Packaging automation can be an investment, depending on the solution you’re looking at. There may be a large upfront cost to purchase an automated packing system, but the money you’ll save elsewhere in your operation will counterbalance this in the long run.

Plus, there are some really cost-effective automation options out there. A great example of this is a water-activated gummed paper tape dispenser – they can come in around £1,500 or less.

You can also opt semi-automatic machines that can be found at a lower price point and they can be a great first step towards automation if you want to dip your toes!

What are the benefits of automated packing systems?

These are some of the general advantages of adding packaging automation to your operation. Depending on the machinery you choose, there can knock-on benefits like saving on transport costs and reducing damages!

The benefits of packaging automation:

- Reduced material costs and waste– packaging automation uses materials more efficiently, so it removes overuse and wastage.

- Improved productivity and reduced packing times – it can speed up elements of the process and reduce the amount of physical touchpoints so packers’ skills can be utilised in other areas. It can also help reduce the need for seasonal temporary labour!

- Save on storage space and materials – using automation means you’re using the right amount of packaging materials needed, so it can free up storage space for other uses and control overall material use.

4 signs that show your small business is ready for automation

- You’re struggling to fulfil orders and customer complaints are rising.

- Your business is creating increasing levels of packaging waste.

- You continually need to hire new staff for your production and/or packing line.

- You experience an uplift in customer complaints about damaged goods (if demand is too high, packing quality could be less reliable).

If your operation meets one or more of these issues, incorporating some form of packaging machinery could be a great solution for your business. Let’s explore some options you have…

Great automation solutions for small businesses

Where to start with packaging automation? We have narrowed down some great options that would be perfect for a small business looking to grow its operation. We have broken this down into process specific systems, so you can decide what would work best for your business.

Tape

You have a lot of options for tape automation, some of these include:

- Manual Water Activated Tape Dispenser – As this most affordable option, it’s not full automation (as the name suggests). You have to adjust the length manually, so this isn’t done for you, unlike other options. It does wet and cut the tape, and it’s a great first step into automation for businesses with lower shipping volumes.

- Automatic Water Activated Tape Dispenser – This desktop dispenser issues pre-set lengths of tape to speed up the application of tape. It also means you will get the correct amount every time, minimising wastage.

Watch this video to learn more about water activated tape:

Void Fill

Automating your void fill can help you cut your packing time, keep up with demand and help you protect your products efficiently. Dependant on the material you choose, how cost effective it is, if there is a consideration towards being environmentally friendly; you can get lots of different types of void fill and machines with various benefits for each business. These are just some examples of what is available.

- Manual Paper Void Fill Dispenser – The Ranpak FillPak TT machine is an entry level option for void fill automation. It’s simple to install and has a small footprint so doesn’t take up much space! It’s operated easily by using a foot pedal, so the void fill can be dispensed directly into the box, and it will it cut down on packing time.

- Automatic Paper void fill dispensers – You can control these via the foot pedals, which automatically fill packs. They can also be programmed to dispense the appropriate length of material for each of your pack options, which reduces the amount of overall material you use.

- Air pillow void fill dispenser – You can also find great automation options for speeding up your packing times when using air pillows, the Pacplan Airwave is a countertop machine, it’s easy to use and willgive your products high levels of protection.

Stretch Wrappers

It may not be something your business needs right now, but it could be helpful in the future to know that you can automate your stretch wrap process.

- If you are manually wrapping between 10-15 pallets per day (or more), it’s time to consider a pallet wrapper. It can dramatically reduce the amount of stretch wrap you are using, as well as reducing manual handling

How to scale up your packaging automation as your business grows?

As your business grows, it can feel overwhelming to keep a hold of your operation, no matter the size. It might seem scary but adding (even a small element) of an automated packing system, is a great way to allow your operation to develop. Over time, you could explore bigger and fully automated options as it grows.

If you’re still unsure or would like to learn more, the Macfarlane Packaging team can provide expert advice on automating your packaging processes and supplying the packaging machinery and warehouse equipment you need. Talk to us today!