5 space-saving packaging tips to combat rising operating costs

This week, we’re considering 5 space-saving tips to optimise your warehouse space…

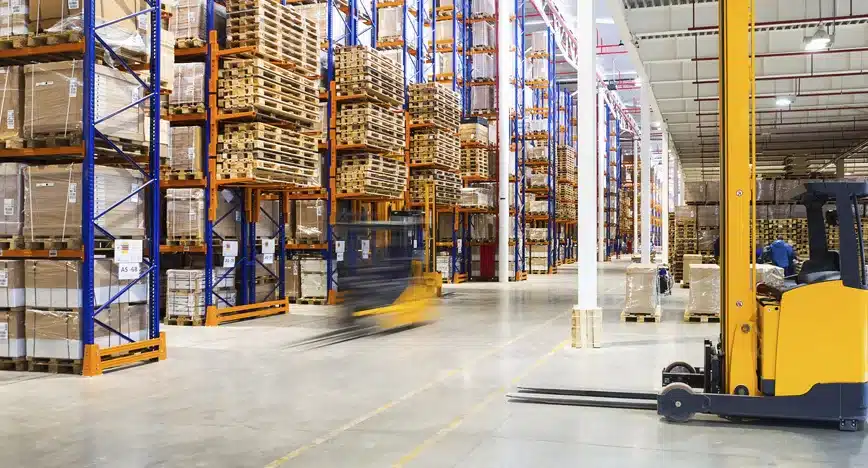

You’ve probably heard the phrase “time is money”, well in this day and age space is money too, particularly if you work in the logistics and warehousing industry.

Pallet storage can typically cost between £1.50 up to £5 per pallet. On top of that, business rates for commercial property classed as large distribution warehousing are set to rise. Due to this, many logistics will be looking to control operational costs associated with space.

Packaging materials usually have a significant footprint in most warehouses relative to their value. Therefore, assessing the packaging supplied that are used in an operation and how they’re stored can be a great way to save warehouse space.

- 1.

- 2.

- 3.

-

4.

5 space-saving packaging tips

- 4.1.

- 4.2.

- 4.3.

- 4.4.

- 4.5.

- 5.

What is the rise in business rates for large distribution warehouses?

Announced in the Autumn 2022 budget, a review of business rates means businesses (like online retailers or logistics companies) who own large distribution warehouses will see rates rise by up to 27%.

The increase is set to impact on some 700,000 properties, driving up the operational costs of online marketplace warehouses.

Why are business rates rising?

The rise in business rates has been announced to address the “clicks vs. bricks” imbalance. It was chosen instead of the touted online sales tax, as increasing business rates was less complex.

For omni-channel retailers, the increase in costs can be offset against the discounts they’ll receive for their bricks and mortar properties. In contrast, it’s going to be more challenging for pure-play e-commerce retailers, where they will be exposed to the increate in rates against a turbulent backdrop.

So, how can businesses combat increasing operational costs and rates rises?

The role of packaging materials in saving space

The packaging materials a business uses can play a big role in saving space in a warehouse. In relation to it’s value, packaging often has a big footprint

Therefore, optimising your packaging and how it is stored can have a big impact on storage costs. Just small changes can amount to big space savings. Using packaging that is lighter and smaller ca help improve pallet yields, minimise the space you need for storage and have a positive knock-on-effect when it comes to transport and courier costs, as well as packaging waste!

Let’s take a look at some packaging tips to help claw back some space in your warehouse…

5 space-saving packaging tips

1. Swap bulky protective packaging products for compact ones

There’s no denying that certain packaging solutions take up a lot of space. For example, materials like polystyrene, bubble wrap rolls or loosefill packing chips can have a significant footprint.

Why not try a compact alternative? Here are a few to consider:

- Air pillows – void full that is inflated on demand can be incredibly space saving. Rolls are compact, easy to store and quick to handle vs. bubble wrap or packing peanuts.

- Paper on demand – compact blocks of paper void fill are another space saving packaging option. One block of paper can often produce as much protective material as six packs of packing chips.

- Flexi-Hex® – this expanding, honeycomb packaging is a great alternative to products like polystyrene bottle packs. It comes flat and you expand it upon use, so it has a much smaller footprint and is 100% recyclable.

2. Review your cardboard box specifications and pallet plans

If you’re using cardboard boxes, have you considered if the design is as effective as it could be? The board grade, box size and orientation of the design can all impact how many boxes you can get on a pallet.

Shaving a few millimeters off the size of a box or changing the orientation could allow you to increase pallet yields. By increasing the number of boxes you can store on a pallet, you’ll need to store fewer pallets in your warehouse. Another positive of a change like this is that costs and emission associated with transporting the boxes can lower too!

3. Optimise existing warehouse space by putting vertical space to use

When we think about warehouse space, we often think about the floor space available to us. But have you factored in how you’re using the vertical space in your packing operation?

Are you utilising the full height of your warehouse? By increasing the height of your racking, you could release floor space for other uses, such as adding in new packing stations.

If your racking is already full height, have you analysed how much space there is between the top pallet and the roof beams? You’ll need at least 6 inches to allow for pallet movement, but if there is more than 6 inches space, it could be a sign to look at how to optimise pallet stacks, to see if you can make use the spare vertical space.

4. Consider if you can reduce how many packaging SKUs you need

Over time, many businesses keep adding more and more packaging SKUs to their operation as demand grows or product ranges evolve. The result? Sometimes you may be storing more packaging supplies than you need.

A good approach is to apply the Pareto Principle. In many situations just 20% of your packaging SKUs will be active lines able to account for packing 80% of your products. You should allocate prime storage to the active packaging lines and review if the other lines are needed.

Another option would be to look at multi-use packaging materials, where the same box or fitting can be adapted for multiple products. For example, variable depth boxes.

5. Take advantage of a stock holding service for packaging materials

If you’re tired of packaging materials clogging up pallet spaces, one of the easiest ways to free up space is to take advantage of a stock holding services.

Distributors, like us, often offer to hold packaging materials on-site and deliver it to your door on a just-in-time basis. This helps minimise space absorbed by packaging supplied and allows you to control cash flow and inventory.

Help controlling storage costs and releasing warehouse space

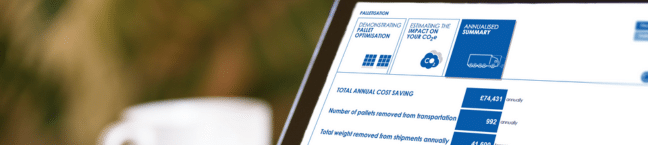

Our experts can help you reduce storage costs and show you the impact new packaging solutions will have on your warehouse space with our Packaging Optimiser. Savings can help you combat business rate rises and manage your operational costs.

Get in touch today to learn more.